CNHL Lipo Batteries

CNHL aim at providing high-quality Li-Po batteries and RC products to all hobby enthusiasts with excellent customer services and competitive prices

Figure 1 is a common defect on the surface of the lithium 4s lipo battery pole piece, the left is an optical image, and the right is an image captured by a thermal imager.

Fig. 1 Common defects on the surface of the pole piece: (a, b) Raised bags/agglomerates; (c, d) Drops/pinholes; (e, f) Metal foreign bodies; (g, h) Uneven coating

(a, b) Raised bales/agglomerates, such defects can occur if the slurry is agitated unevenly or the coating feed rate is unstable. Agglomeration of binder and carbon black conductive agent results in low active ingredient content and light weight pole pieces.

(c, d) Dropouts/pinholes, these defect areas are not coated and are usually created by air bubbles in the slurry. They reduce the amount of active material and expose the current collector to the electrolyte, thereby reducing the electrochemical capacity.

(e, f) Metal foreign matter, metal foreign matter introduced in slurry or equipment and environment, metal foreign matter is very harmful to lithium 4s lipo battery. The larger-sized metal particles directly pierce the separator, resulting in a short circuit between the positive and negative electrodes, which is a physical short circuit. In addition, when metal foreign matter is mixed into the positive electrode, the positive electrode potential increases after charging, the metal dissolves, diffuses through the electrolyte, and then precipitates on the negative electrode surface, and finally pierces the diaphragm and forms a short circuit, which is a chemical dissolution short circuit. The most common metal foreign bodies on the 4s lipo battery factory site are Fe, Cu, Zn, Al, Sn, SUS, etc.

(g, h) Uneven coating, such as insufficient mixing of the slurry, streaks are likely to appear when the particle fineness is large, resulting in uneven coating, which will affect the consistency of the capacity of the 4s lipo battery, and even appear to have no coating at all The stripes have an impact on both capacity and safety.

Infrared (IR) thermal imaging is used to detect tiny defects on the dry pole pieces that could damage the performance of lithium 4s lipo batteries. During online inspection, if electrode defects or contaminants are detected, mark them on the pole pieces, remove them in subsequent processes, and feed them back to the production line to adjust the process in time to eliminate defects. Infrared is an electromagnetic wave that has the same nature as radio waves and visible light. Using a special electronic device to convert the temperature distribution of the object surface into an image visible to the human eye, and display the temperature distribution of the object surface in different colors, is called infrared thermal imaging technology, and this electronic device is called an infrared thermal imager. All objects above absolute zero (-273°C) emit infrared radiation.

As shown in Figure 2, an infrared thermal imager (IR Camera) uses an infrared detector and an optical imaging objective lens to receive the infrared radiation energy distribution pattern of the measured target object and reflect it on the photosensitive element of the infrared detector to obtain an infrared thermal image. , this thermal image corresponds to the thermal distribution field on the surface of the object. When there are defects on the surface of the object, there will be a temperature shift in this area. Therefore, this technology can also be used to detect defects on the surface of the object, especially for some defects that cannot be resolved by optical detection methods. When the dry pole piece of lithium 4s lipo battery is tested online, first the pole piece is irradiated by a flash lamp, and the surface temperature changes, and then the surface temperature is detected by a thermal imager. The thermal distribution image is visualized, and the image is processed and analyzed in real time, and surface defects are detected and marked in time. D. Mohanty's research installed a thermal imager at the outlet of the drying oven of the coater to detect the temperature distribution image on the surface of the pole piece.

Figure 2. Schematic diagram of the appearance of the surface of the pole piece detected by the thermal imager

Figure 3(a) is the temperature distribution of the coating surface of the NMC cathode electrode detected by the thermal imager, which contains a very small defect that cannot be distinguished by the naked eye. The temperature distribution curve corresponding to the line segment on the way is shown in the inset, and there is a temperature spike at the defect point.

In the box corresponding to the image in Fig. 3(b), the temperature locally increases, which corresponds to the defect on the surface of the pole piece.

Figure 4 is a graph of the surface temperature distribution of the negative pole piece showing the existence of defects, wherein the peaks with increased temperature correspond to bubbles or agglomerates, and the regions with decreased temperature correspond to pinholes or dropouts.

Figure 3 Thermal imaging temperature distribution on the surface of the positive electrode

Figure 4 Thermal imaging temperature distribution on the surface of the negative pole piece

It can be seen that thermal imaging detection of temperature distribution is a good method for detecting surface defects of pole pieces, and can be used for quality control of pole piece manufacturing.

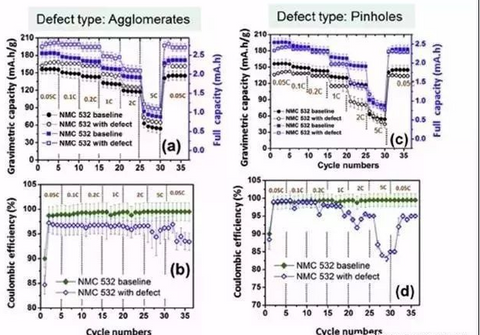

Figure 5 is the influence curve of agglomerates and pinholes on the rate capacity and coulombic efficiency of 4s lipo battery. The agglomerates can actually increase the capacity of 4s lipo battery, but will reduce the coulombic efficiency. The pinhole reduces the capacity and coulombic efficiency of the 4s lipo battery, and the coulombic efficiency drops greatly at high rates.

Fig.5 Influence of positive agglomerates and pinholes on the rate capacity and coulombic efficiency of 4s lipo battery

Fig.6 is the influence curve of uneven coating and metal foreign matter Co and Al on the rate capacity and coulombic efficiency of 4s lipo battery, uneven coating The unit mass capacity of the 4s lipo battery is reduced by 10%-20%, but the capacity of the entire 4s lipo battery has dropped by 60%, which shows that the quality of living things in the pole piece has been significantly reduced. Metal Co foreign matter reduces the capacity and Coulomb efficiency, and even at high rates of 2C and 5C, there is no capacity at all, which may be due to the formation of alloys by metal Co in the electrochemical reaction, which hinders delithiation and lithium intercalation, or it may be blocked by metal particles. The pores of the separator cause micro-short circuits.

Fig.6 Influence of uneven cathode coating and metallic foreign matter Co and Al on the rate capacity and coulombic efficiency of 4s lipo battery

Summary of positive pole piece defects: Aggregates in the positive pole piece coating reduce the Coulombic efficiency of the 4s lipo battery. Pinholes in the cathode coating reduce the Coulombic efficiency, resulting in poor rate performance, especially at high current densities. Non-uniform coatings show poor rate performance. Metal particle contamination can cause micro-short circuits, which can greatly reduce the capacity of the 4s lipo battery.

Agglomeration: at 2C, the capacity retention rate of the non-defective pole piece 4s lipo battery is 70% for 200 cycles, and the defective 4s lipo battery is 12%. At 5C, the capacity maintenance rate of the non-defective pole piece 4s lipo battery is 50% for 200 cycles, and the defect 4s lipo battery is 50%. battery14%.

Pinhole: The capacity decay is obvious, but not as fast as the agglomerate defect. The capacity retention rate of 2C and 5C after 200 cycles is 47% and 40%, respectively.

Metal foreign body: The capacity of metal foreign body is almost 0 after several cycles of metal foreign body, and the 5C cycle capacity of metal foreign body Al foil decreases significantly.

Leaky foil stripes: Under the same leakage foil area, compared with a large stripe (47% capacity retention rate for 200 cycles at 5C cycle), the capacity of 4s lipo battery with multiple small stripes decreases faster (200 cycles at 5C cycle). The capacity retention rate of the second cycle is 7%). This shows that the greater the number of stripes, the greater the impact on the cycle of the 4s lipo battery.

Well, the above is the full content of the types of 4s lipo battery pole piece defects, their impact and detection methods that CNHL brought to you today. I believe that after reading the whole text, everyone's understanding of the 4s lipo battery pole piece has deepened. More lithium batteries The information is continuously updated, see you in the next issue.

CNHL aim at providing high-quality Li-Po batteries and RC products to all hobby enthusiasts with excellent customer services and competitive prices

Specifications: Stock Number: 500706EC5 Capacity: 5000mAh Voltage: 22.2V / 6-Cell / 6S1P Discharge Rate: 70C Continual / 140C Burst Charge Rate: ...

View full detailsSpecifications: Stock Number: 1351506PZ Capacity: 1350mAh Voltage: 22.2V / 6-Cell / 6S1P Discharge Rate: 150C Continual / 300C Burst Charge Rate:...

View full detailsSpecifications Stock Number: 1301306BK Capacity: 1300mAh Voltage: 22.2V / 6-Cell / 6S1P Discharge Rate: 130C Continual / 260C Burst Charge Rate: 5...

View full detailsSpecifications: Stock Number: 1501204 Capacity: 1500mAh Voltage: 14.8V / 4-Cell / 4S1P Discharge Rate: 120C Continual / 240C Burst Charge Rate: 5C...

View full detailsSpecifications: Stock Number: 220303BK Capacity: 2200mAh Voltage: 11.1V / 3-Cell / 3S1P Discharge Rate: 30C Continual / 60C Burst Charge Rate: 5C ...

View full detailsThe VOLANTEX BF109 4-Channel RC Plane RTF brings one of the most iconic WWII fighters into a compact, beginner-friendly package. With a 400 mm w...

View full detailsThe Volantex RC Plane P51D V2 RTF is a compact WWII-style warbird built to make learning to fly as relaxed as possible. With a 400 mm wingspan, E...

View full detailsThe MF-A84 690mm Brushless RC Airplane is a warbird-style model inspired by classic fighters such as the P-47 Thunderbolt and Ki-84. With a powe...

View full detailsSpecifications: Stock Number: 6001006EC5 Capacity: 6000mAh Voltage: 22.2V / 6-Cell / 6S1P Discharge Rate: 100C Continual / 200C Burst Charge Rate...

View full detailsSpecifications: Stock Number: 6001004 Capacity: 6000mAh Voltage: 14.8V / 4-Cell / 4S1P Discharge Rate: 100C Continual / 200C Burst Charge Rate: 5...

View full details

Leave a comment